The Versatile World of PP Sheets: Manufacturing, Applications, and Market Dynamics

PP sheets, made from polypropylene, are an indispensable material in various industries, showcasing a blend of durability and versatility. These sheets are used in an array of applications, from packaging to construction, due to their unique properties like chemical resistance, lightweight, and ease of fabrication. Understanding the role of polypropylene prices, the manufacturing processes employed by PP sheets manufacturers, and the applications of these sheets is crucial for businesses looking to optimize their operations or enhance product offerings. In this Pulkit Plastic Products, we will explore the multifaceted world of PP sheets, emphasizing their characteristics, uses, and market trends.

Understanding Polypropylene Sheets: Characteristics and Benefits

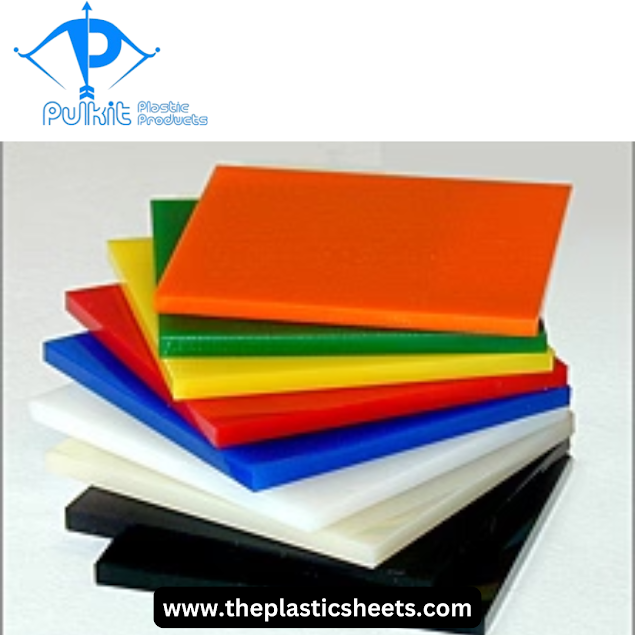

Polypropylene sheets, often referred to as PP sheets, are produced from polypropylene resin, a thermoplastic polymer known for its lightweight and robust nature. The unique properties of PP sheets include high impact resistance, excellent tensile strength, and resistance to moisture and a variety of chemicals. Additionally, these sheets can be produced in various thicknesses and colors, catering to diverse consumer needs and applications.

One of the primary benefits of PP sheets is their versatility. They are widely used in industries as protective coverings, packing materials, and even construction components. The sheets are preferred over materials like PVC and glass due to their lighter weight, making them easier to handle and transport. Furthermore, their resistance to UV radiation minimizes degradation over time, making them suitable for outdoor applications as well.

The ability to print on PP sheets also enhances their appeal, allowing businesses to add branding and promotional messages directly onto the material. This characteristic is particularly advantageous in industries where visibility and marketing play a crucial role, such as retail and advertising. Overall, the physical and aesthetic properties of PP sheets contribute significantly to their expansive utility across various sectors.

Diverse Applications of PP Sheets

The applications of PP sheets manufacturer are vast and varied, intersecting with several industries. In packaging, they serve to create containers, trays, and protective packaging for fragile or sensitive items. The moisture resistance of these sheets ensures that products remain safe during storage and transport, making them ideal for food packaging and other sensitive commodities.

In the agricultural sector, PP sheets are often utilized for greenhouse coverings and mulch films. These sheets provide protection against environmental factors while allowing adequate light transmission for effective plant growth. The durability and UV resistance of polypropylene are key elements that contribute to successful agricultural production.

Additionally, the construction industry utilizes PP sheets for wall partitions, insulation foils, and scaffolding applications. Their lightweight nature reduces shipping costs while maintaining structural integrity. Environmentally friendly construction practices further enhance the demand for PP sheets as a recyclable option compared to traditional materials.

Moreover, in the medical field, PP sheets are increasingly employed to manufacture sterile packaging for medical devices, ensuring durability and hygiene. The ability to seal tightly and resist moisture makes them an essential component in maintaining product safety and integrity in healthcare applications.

Manufacturing Processes of PP Sheets

The manufacturing process of PP sheets typically involves several critical stages: extrusion, cooling, and cutting. Initially, polypropylene resin is fed into an extruder, where it is melted and forced through a flat die to create a continuous sheet. This extrusion process is vital for achieving uniform thickness and properties across the entire sheet.

After extrusion, the sheet is cooled and solidified. Several cooling methods can be employed, including air cooling or water bath cooling, depending on the desired characteristics of the final product. Air cooling is preferred for lower thicknesses, while water baths are used for thicker sheets that require rapid cooling to achieve optimal rigidity.

Once cooled, the sheets are cut into specific dimensions based on customer requirements. This process can also include additional treatments, such as corona treatment for enhanced print adhesion or lamination for added protection against moisture and UV rays. Quality assurance measures are crucial at every manufacturing stage to ensure that the sheets meet industry standards and customer specifications.

PP sheets manufacturers continuously invest in advanced technologies and equipment to maximize production efficiency while maintaining high quality. Automation, in particular, has streamlined the manufacturing processes, allowing for faster production rates and more consistent results.

Market Dynamics and Polypropylene Prices

Understanding Polypropylene prices is essential in evaluating the market for PP sheets. Prices can fluctuate due to a variety of factors, including the cost of raw materials, oil prices, and supply chain dynamics. Polypropylene is derived from petroleum, meaning changes in the crude oil market can directly impact production costs and, subsequently, the pricing of polypropylene sheets.

Another significant factor affecting prices is the competitive landscape of PP sheets manufacturers. As more companies enter the market, competition can lead to price reductions; however, the need for high-quality products often balances this trend. Businesses that prioritize durability and compliance with industry standards may be willing to invest in higher-quality PP sheets, even if they come at a premium price point.

Seasonal demand fluctuations can also influence polypropylene prices. Industries such as agriculture typically see a surge in demand for PP sheets during planting seasons, which can create short-term price increases. Manufacturers should stay informed about these market trends to optimize their inventories and pricing strategies effectively.

Furthermore, as sustainability becomes an increasingly pressing concern, companies focusing on eco-friendly manufacturing processes may find opportunities for niche pricing. Consumers and businesses are showing a preference for sustainable materials, which can leverage the market share of manufacturers willing to innovate toward greener solutions.

Innovations and Trends in the Industry

In recent years, significant innovations have emerged in the manufacturing and application of PP sheets. One notable trend is the increased focus on creating multifunctional sheets that can serve specialized needs across various industries. For instance, sheets designed with anti-static properties are gaining popularity in the electronics sector, where protection against static discharge is crucial.

Additionally, there has been a growing movement toward using recycled polypropylene in the production of PP sheets. Manufacturers are exploring ways to incorporate post-consumer or post-industrial waste into their raw materials while still achieving the quality and performance characteristics desired in new products. This approach not only supports sustainability goals but also reduces reliance on virgin materials, potentially lowering production costs over time.

The integration of smart technologies into PP sheets is also an emerging trend. These innovations include embedding sensors within the material to monitor environmental conditions such as temperature and humidity. Smart PP sheets have the potential to revolutionize packaging and storage solutions by providing real-time data to businesses regarding product safety and storage conditions.

Such advancements indicate a bright future for PP sheets, with manufacturers embracing the convergence of technology and materials science to produce higher-value products that resonate with modern market needs.

The Importance of Choosing the Right PP Sheets Manufacturer

Selecting the right polypropylene sheet manufacturer is crucial for businesses seeking high-quality PP sheets. Factors such as quality control, production capabilities, and customer service should all be considered during the selection process. Reliable manufacturers often provide detailed specifications for their products, ensuring that customers can make informed decisions based on their needs.

Furthermore, manufacturers that prioritize sustainability and eco-friendly practices can enhance their competitive advantage in a market increasingly focused on environmental responsibility. Businesses should seek manufacturers who are transparent about their sourcing practices and production methods.

Additionally, building a long-term relationship with a reputable manufacturer can yield several benefits, including access to customized solutions, timely deliveries, and favorable pricing agreements. When manufacturers understand their clients’ specific requirements and industries, they can also provide insights and recommendations for optimal product applications.

Staying informed about advancements in manufacturing technologies and industry standards will be crucial for companies as they navigate the dynamic landscape of polyolefin materials. The right partnership can lead to improved outcomes for businesses and ensure that they have the resources needed to succeed.

Conclusion

The Polypropylene sheet manufacturer are an essential material in a variety of industries, known for their strength, versatility, and affordability. The characteristics of these sheets, underpinned by their manufacturing processes and applications, demonstrate their importance in packaging, agriculture, construction, and more. Understanding the implications of polypropylene prices and selecting a reputable PP sheets manufacturer will help businesses make informed decisions while fostering growth in their respective sectors.

As innovation continues to shape the polypropylene market, manufacturers must adapt to changing consumer preferences and embrace sustainability in their practices. The future of PP sheets is bright, driven by technological advancements and a growing commitment to creating environmentally responsible materials within the packaging and building industries.

Frequently Asked Questions (FAQs)

1. What are the main advantages of using PP sheets?

PP sheets offer a range of advantages, including lightweight durability, moisture resistance, chemical resistance, and the ability to withstand UV exposure. They are also customizable in terms of thickness and color, making them suitable for a wide array of applications.

2. How do polypropylene prices affect PP sheet manufacturing?

Polypropylene prices are influenced by several factors, including oil prices and market demand. Fluctuations in these prices can directly impact the cost of producing PP sheets, leading to variations in pricing for customers.

3. Can PP sheets be recycled?

Yes, PP sheets are recyclable. Many manufacturers promote recycling initiatives and aim to incorporate recycled materials into their production processes to support sustainability efforts.

4. What should I consider when choosing a PP sheets manufacturer?

When selecting a PP sheets manufacturer, consider factors such as product quality, production capabilities, sustainability practices, customer service, and the ability to provide customized solutions to meet your specific needs.

In conclusion, PP sheets continue to play a vital role in multiple sectors, providing effective solutions while addressing sustainability trends in the market. With ongoing innovation and technological advancements, the future for polypropylene sheets looks optimistic, with opportunities for broader applications and enhanced performance characteristics.

.png)

Comments

Post a Comment