An Introduction to PP Multifilament Yarn: Versatility and Applications

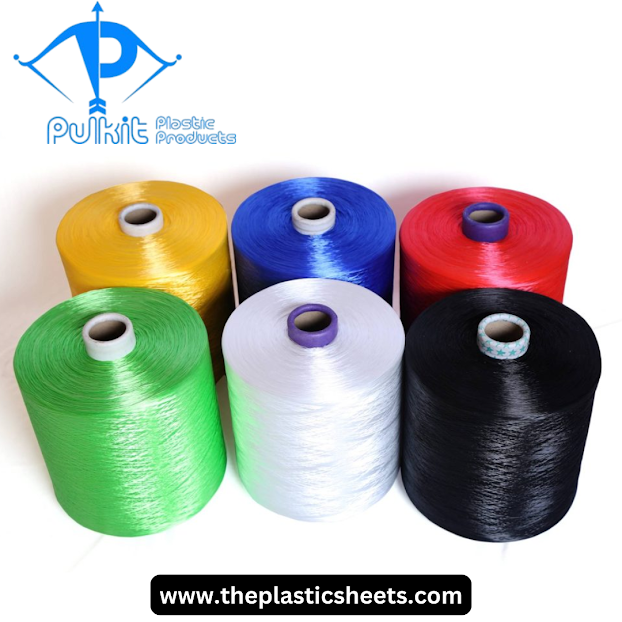

What is PP Multifilament Yarn?

PP multifilament yarn, also known as polypropylene multifilament yarn, is a synthetic fiber made from the polymerization of propylene monomers. This yarn consists of multiple filaments tightly twisted together to form a coherent structure, resulting in a durable and robust material ideal for a wide range of applications. The lightweight nature of polypropylene, combined with the strength and flexibility of multifilament constructions, makes PP filament yarn an excellent choice for industries that rely on long-lasting materials.

Throughout its manufacturing process, Pulkit Plastic Products is extruded through fine spinnerets to create numerous filaments. These filaments are then spun together to form a cohesive yarn that exhibits excellent tensile strength and resistance to wear and tear. The multifilament structure enhances the overall performance, making PP multifilament yarn suitable for demanding applications in diverse fields.

Properties of PP Multifilament Yarn

The unique properties of PP multifilament yarn make it highly sought after in various sectors. One of its most notable characteristics is its high strength-to-weight ratio, which allows it to perform well under stress while remaining lightweight. This quality is particularly important in applications such as fishing nets, industrial fabrics, and ropes, where durability is essential without the added weight.

Another important property of polypropylene multifilament yarn is its resistance to moisture and humidity. Unlike natural fibers, which tend to absorb water, PP filament yarn is hydrophobic. This feature enables it to maintain its integrity in wet conditions, reducing the risk of mildew and mold formation and prolonging the durability of the finished products. Moreover, its excellent UV resistance aids in preventing degradation from prolonged sun exposure, making it suitable for outdoor applications.

Additionally, PP multifilament yarn is chemically resistant to a wide range of substances, including acids, alkalis, and solvents. This characteristic is advantageous for industrial applications where exposure to harsh chemicals is common, ensuring that the yarn maintains its functionality even in challenging environments.

Applications of PP Multifilament Yarn

The versatility of PP multifilament yarn translates into a broad array of applications across numerous industries. In the textiles industry, it is commonly used to produce fabrics, webbing, and various types of apparel. The lightweight and durable nature of the yarn makes it an ideal choice for sportswear, outdoor clothing, and leisure items.

In the fishing industry, PP filament yarn is used to manufacture fishing nets and ropes. The strength and resistance to moisture play a vital role in ensuring the durability of fishing gear subjected to harsh environmental conditions. These nets and ropes are essential for both commercial fishing operations and recreational activities, demonstrating the indispensable role of PP multifilament yarn in this sector.

Furthermore, PP multifilament yarn finds its way into agricultural applications, including the production of tarpaulins and protective coverings. Its resistance to UV rays ensures that agricultural products are well protected from the sun's harmful effects. Additionally, the yarn is employed in the creation of geotextiles, which help in soil stabilization, erosion control, and drainage in various landscaping projects.

Comparing PP Multifilament Yarn with Other Fibers

When it comes to yarn selections, understanding the differences between PP multifilament yarn and other types of fibers is crucial for manufacturers and consumers. Natural fibers like cotton and linen offer softness and breathability but can be more susceptible to moisture retention and environmental conditions. On the other hand, synthetic fibers such as polyester and nylon provide comparable tensile strength but can often lack the environmental resistance that polypropylene offers.

One of the primary advantages of PP multifilament yarn is its lower environmental impact in certain applications. While the production of synthetic yarns generates some environmental concerns, the durability and longevity of polypropylene allow for longer product lifespans which can mitigate some adverse effects associated with frequent replacements of natural fibers that wear out more quickly.

Furthermore, PP filament yarn is often more cost-effective than many alternatives, which can be crucial for businesses looking to balance quality and budget. The combination of affordability and performance makes it an attractive option across various sectors.

Production Process of PP Multifilament Yarn

The production of PP multifilament yarn involves intricate processes that require advanced technology and precision. Initially, propylene polymer is polymerized to create polypropylene granules. These granules are then fed into an extruder where they are heated and melted before being forced through a spinneret. The spinneret contains numerous holes that shape the molten polymer into continuous filaments.

Once extruded, the filaments are rapidly cooled to solidify and then drawn or stretched to enhance their strength. This drawing process aligns the molecular structure, thereby improving the mechanical properties of the yarn. After that, the filaments are twisted together to produce the multifilament yarn, which can be further processed for dyeing or finishing depending on the end application required.

Finally, the yarn undergoes quality checks to ensure that it meets specific industry standards. These tests typically assess parameters such as tenacity, elongation, and color fastness, providing assurance that the Polypropylene multifilament yarn is suitable for its intended use.

Sustainability and Environmental Impact of PP Multifilament Yarn

Sustainability is becoming increasingly important in all industries, and the yarn industry is no exception. While synthetic fibers like polypropylene are derived from petrochemical sources, there is a growing trend toward recycling and sustainability in the production of PP multifilament yarn. Many manufacturers are beginning to explore options for using recycled polypropylene, which not only reduces waste but also decreases the overall carbon footprint.

Moreover, enhanced production methods that minimize energy consumption during the manufacturing process are being adopted within the industry. Companies are investing in more efficient machinery and processes to meet sustainability goals and respond to consumer demand for greener products.

In addition, the durability of PP multifilament yarn contributes to sustainability; since products made from this yarn tend to have increased longevity, they require less frequent replacement, effectively reducing waste over time. As global awareness of environmental issues continues to grow, the development of sustainable practices in the production of PP filament yarn will be critical to addressing these concerns.

The Future of PP Multifilament Yarn

The future of PP multifilament yarn appears promising, with expanding applications in various industries and continued advancements in manufacturing technology. As the demand for lightweight, durable materials grows, PP filament yarn is well-positioned to meet these requirements. Emerging trends indicate a shift towards utilizing yarn in innovative applications, such as smart textiles that incorporate electronic components.

Moreover, ongoing research and development efforts are focused on enhancing the properties of PP multifilament yarn for specialized applications, including high-performance fabrics for extreme environments. Innovations in color treatment, texture, and compatibility with other materials may also expand the versatility of PP multifilament products in the coming years.

As the industry adapts to changing consumer preferences, the potential for PP multifilament yarn grows. The integration of technology along with sustainable practices will likely play a pivotal role in shaping the future landscape of this essential material.

Conclusion

PP multifilament yarn stands out as a robust synthetic material with numerous advantages, including high strength, resistance to moisture, and versatility for various applications. Its unique properties make it a popular choice in textiles, fishing, agriculture, and more. As industries continue to evolve and prioritize sustainability, the production of polypropylene multifilament yarn is also adapting to meet these demands.

With innovative manufacturing techniques and a focus on reducing environmental impact, the future of PP filament yarn looks bright. Whether it is through expanding applications in high-performance materials or embracing sustainable practices, PP multifilament yarn will remain an integral part of various industries, providing reliability and durability where it matters most.

Frequently Asked Questions

What is PP multifilament yarn primarily used for?

- PP multifilament yarn is commonly used in various applications, including textiles, fishing nets, industrial fabrics, agricultural products, and geotextiles due to its strength, durability, and moisture resistance.

How does PP multifilament yarn compare to natural fibers?

- PP multifilament yarn has a higher tensile strength, is moisture-resistant, and is less prone to wear and tear compared to natural fibers, making it a more durable alternative in many applications.

Is PP multifilament yarn environmentally friendly?

- While polypropylene is derived from petrochemicals, the sustainability of PP multifilament yarn can be enhanced by utilizing recycled polypropylene and improving production processes to minimize energy consumption.

What factors influence the quality and performance of PP multifilament yarn?

- Key factors include the production process (such as extrusion and drawing), the quality of raw materials used, and any additional treatments applied during manufacturing, all of which affect the yarn's strength, flexibility, and overall durability.

.png)

Comments

Post a Comment